What Is a Plastic Shredder and Why It Matters in Modern Manufacturing

Introduction: The Role of Plastic Shredders in Today's Industry

In an era where manufacturing is under increasing pressure to be faster, cleaner, and more sustainable, the importance of materials processing technology has grown exponentially. Among the most vital machines driving these trends is the plastic shredder. But what exactly is a plastic shredder, and why has it become so indispensable in modern production lines?

Whether you're in recycling, automotive, footwear, packaging, or electronics, understanding the value of plastic shredding technology is key to improving operational efficiency and contributing to a circular economy. In this article, we’ll break down what a plastic shredder is, how it works, and why more manufacturers are making it a standard part of their processing workflow.

What Is a Plastic Shredder?

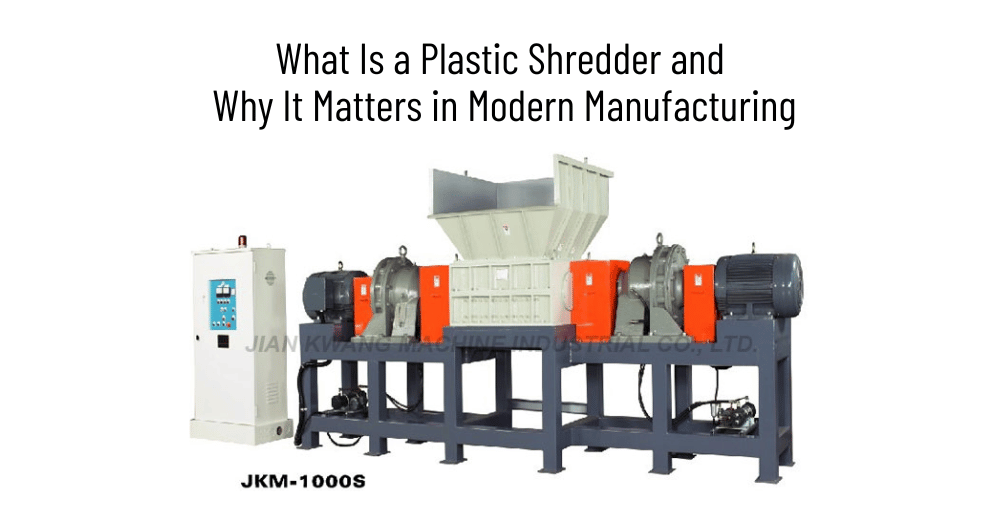

A plastic shredder is an industrial machine designed to reduce plastic waste—such as defective parts, runners, rejected products, or post-consumer plastic—into smaller, manageable flakes or chips. These shredded materials can then be reused in production or further processed (e.g., cleaned, pelletized, or compounded).

Plastic shredders come in various configurations depending on the size, type, and hardness of the materials being processed. The most common types include:

- Single-shaft shredders – For general-purpose volume reduction

- Double-shaft shredders – For higher torque and tougher materials

- Granulators – For finer cutting after coarse shredding

- Customized shredder systems – Integrated with crushers, conveyors, and separators

The machine typically consists of a rotating cutting chamber with hardened steel blades or knives, a motor, gearbox, feeding hopper, and safety features to handle high-throughput material destruction reliably.

Why Plastic Shredders Matter in Modern Manufacturing

1. Waste Reduction and Reuse

Shredders play a foundational role in plastic recycling by converting bulky or irregular plastic waste into a uniform size, making it suitable for downstream processes like washing, extrusion, or pelletizing. This supports in-house recycling initiatives and minimizes waste sent to landfills.

2. Cost-Saving Through In-House Recycling

Instead of outsourcing plastic waste treatment, manufacturers using shredders can reclaim production scrap, reprocess it, and feed it back into production—saving on raw material costs and reducing procurement needs.

3. Material Preparation for Efficient Processing

Consistent particle size from shredding ensures that downstream equipment like pelletizers, mixers, or extruders can operate more efficiently. This leads to smoother operations, reduced wear on machinery, and higher product quality.

4. Support for Sustainable Manufacturing Goals

Modern factories are expected to contribute to environmental targets such as zero-waste policies or ESG initiatives. Shredders are essential tools for achieving these goals by enabling closed-loop production and reducing reliance on virgin plastics.

5. Versatility Across Materials and Industries

Shredders are capable of handling a wide variety of plastics:

- Thermoplastics (e.g., PE, PP, ABS)

- Foamed materials (e.g., EVA, TPR)

- Composite or fiber-reinforced plastics

- Packaging film, runners, bulky rejects

This makes them valuable not only in recycling plants, but also in industries like footwear, electronics, automotive, and consumer goods.

Shredder Machines in the Jian Kwang Ecosystem

At Jian Kwang Machine Industrial Co., Ltd., we recognize the shredder as more than just a machine—it’s the gateway to high-efficiency recycling systems. Our shredders are often integrated into complete lines that include:

- Crusher + Shredder + Kneader + Extruder

- Water-ring pelletizing systems

- Material sorting and filtering modules

Each system is designed to suit different material flows, whether you’re handling soft EVA foam or rigid industrial scrap.

Looking Ahead: What’s Next in the Shredder Series

This article lays the groundwork for understanding the role of plastic shredders. In our upcoming articles, we will explore:

- Real-world applications across multiple industries

- How to choose the right shredder based on material and capacity

- The core innovations in Jian Kwang’s shredder designs

- How shredders support ESG goals in manufacturing

Conclusion

In summary, the plastic shredder is no longer a niche piece of equipment—it’s a core component in the shift toward smarter, more sustainable manufacturing. Whether you're focused on reducing waste, cutting costs, or closing the loop on plastic use, investing in the right shredding technology is a smart move.

By understanding the basics and seeing its role in modern workflows, manufacturers can make informed decisions and unlock new levels of efficiency. Stay tuned for the next article in our Shredder Series as we explore how these machines are revolutionizing real-world industries.